BEST provides comprehensive process upgrade and maintenance services, covering the complete brewing process from raw material handling to beer clarification. Leveraging extensive engineering experience and strong execution capabilities, we have successfully delivered equipment upgrade and system retrofit projects for many well-known brewing groups, including Tsingtao Brewery Group, China Resources Snow Breweries, AB InBev, Yanjing Brewery, and Carlsberg.

We are committed to helping breweries and beverage producers worldwide improve operational efficiency, ensure stable and consistent product quality, extend equipment service life, and achieve long-term reliable production operations.

Through system-level and key equipment upgrades, we improve energy utilization efficiency and reduce energy consumption per unit of output.

By optimizing process flows and equipment configuration, we reduce raw material and operational losses while improving overall production efficiency.

Strengthening control of critical process steps, improving clarity performance, and reducing microbiological risks to ensure stable and consistent product quality.

Utilizing proven process design and automated control systems to reduce failure rates and ensure continuous, reliable production.

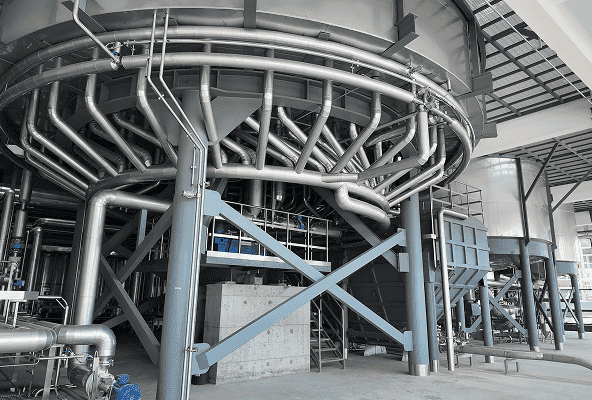

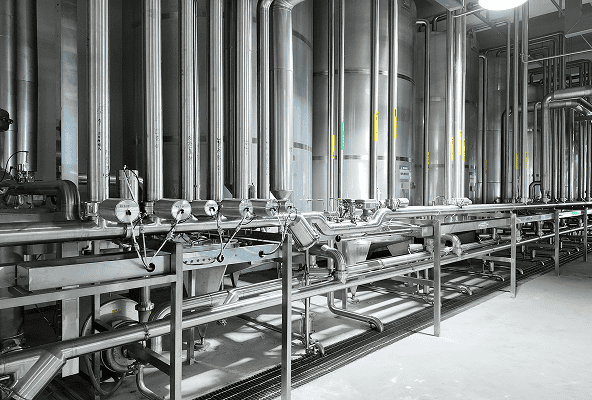

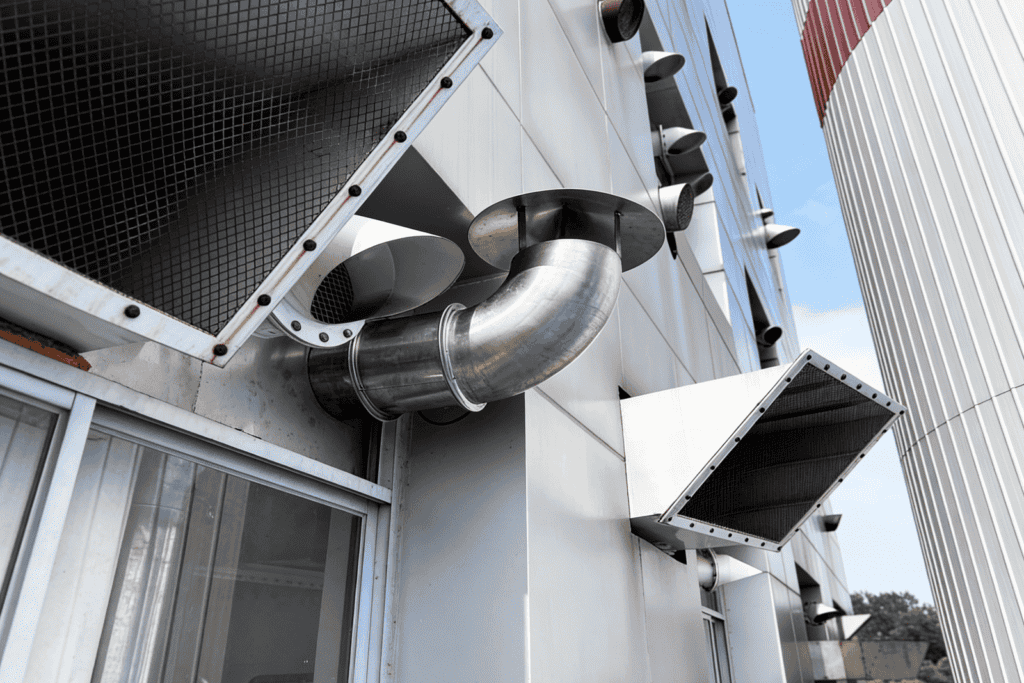

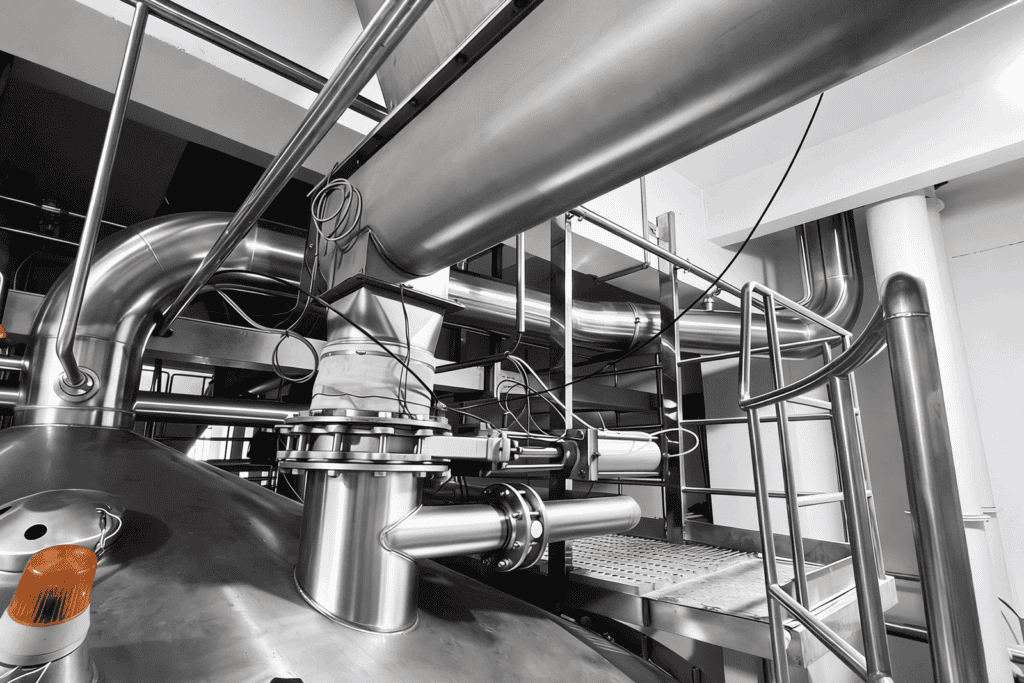

In system upgrade and energy efficiency improvement projects, heat recovery is one of the core modules we prioritize. By systematically utilizing recoverable heat sources generated during the production process, we help breweries significantly improve energy efficiency, reduce operating costs, and achieve a more sustainable production model.

Focusing on critical process steps, excess heat generated during production is centrally recovered and reused. Without compromising process stability or product quality, this approach enables efficient and circular utilization of energy.

*Specific solutions are customized based on brewery scale, process configuration, and on-site conditions.

We provide proven and reliable heat recovery system solutions that can be flexibly integrated into existing systems or incorporated into new installations.

Working in coordination with core equipment and automated control systems, our solutions ensure process requirements are met while enabling the long-term, stable implementation of energy-saving objectives.

Copyright © 2012 – 2025 Qingdao Best Brewer Engineering Technology Co., Ltd. All Rights Reserved.