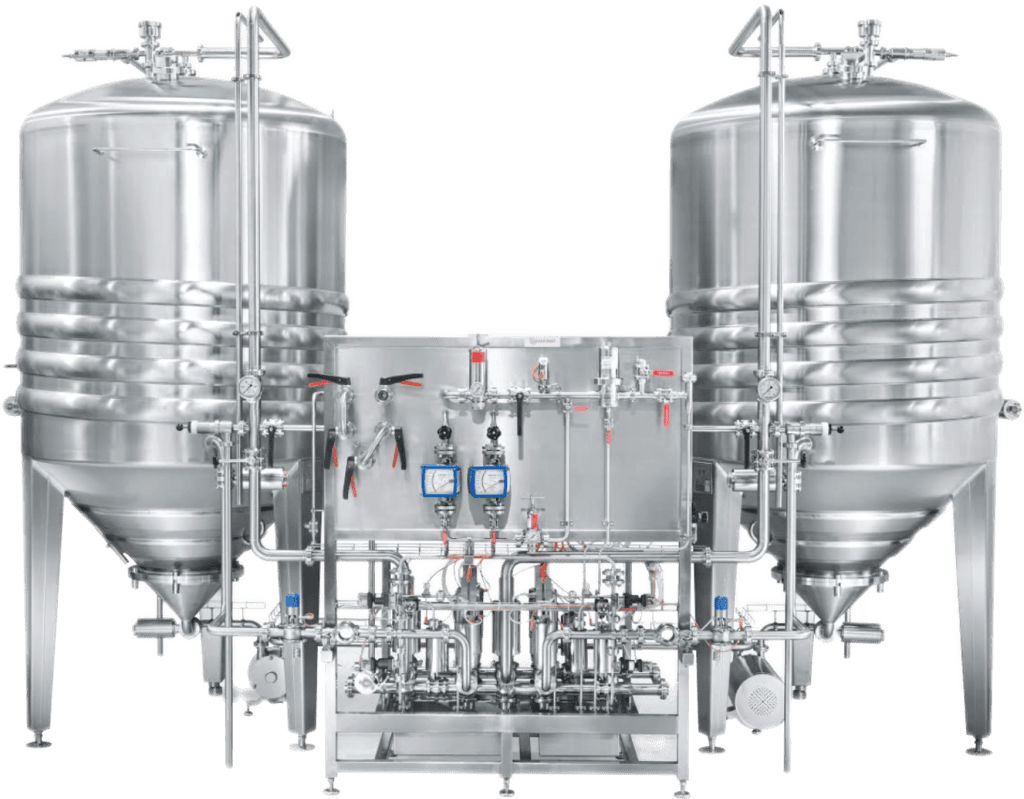

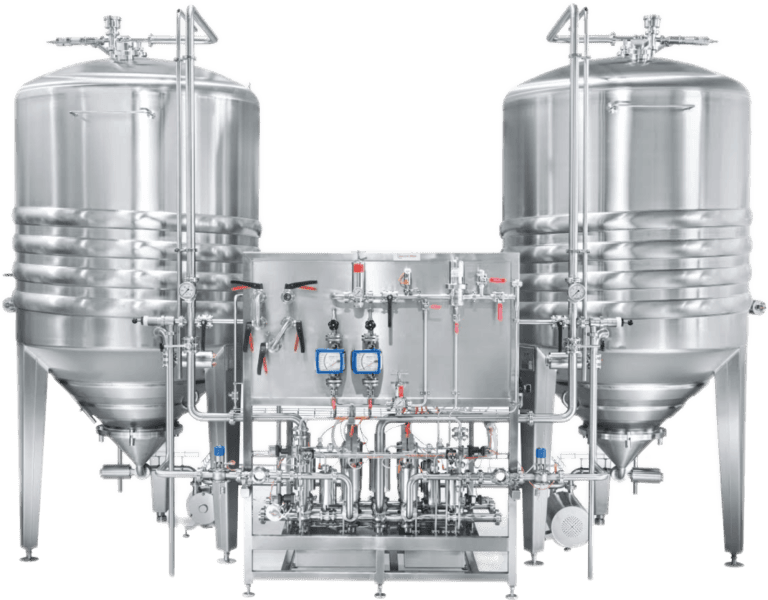

The yeast propagation system is designed for use in large-scale breweries to cultivate and expand pure yeast under strict aseptic conditions. After sterilization of the tank, pipelines, and valves, the system introduces wort and compressed sterile air to create a controlled environment for yeast growth. It supports two-level, three-level, or multi-level propagation, with single-batch capacities ranging from 0.2HL to 200HL. This ensures high cell vitality, purity, and reproducibility when yeast is pitched into fermentation tanks.

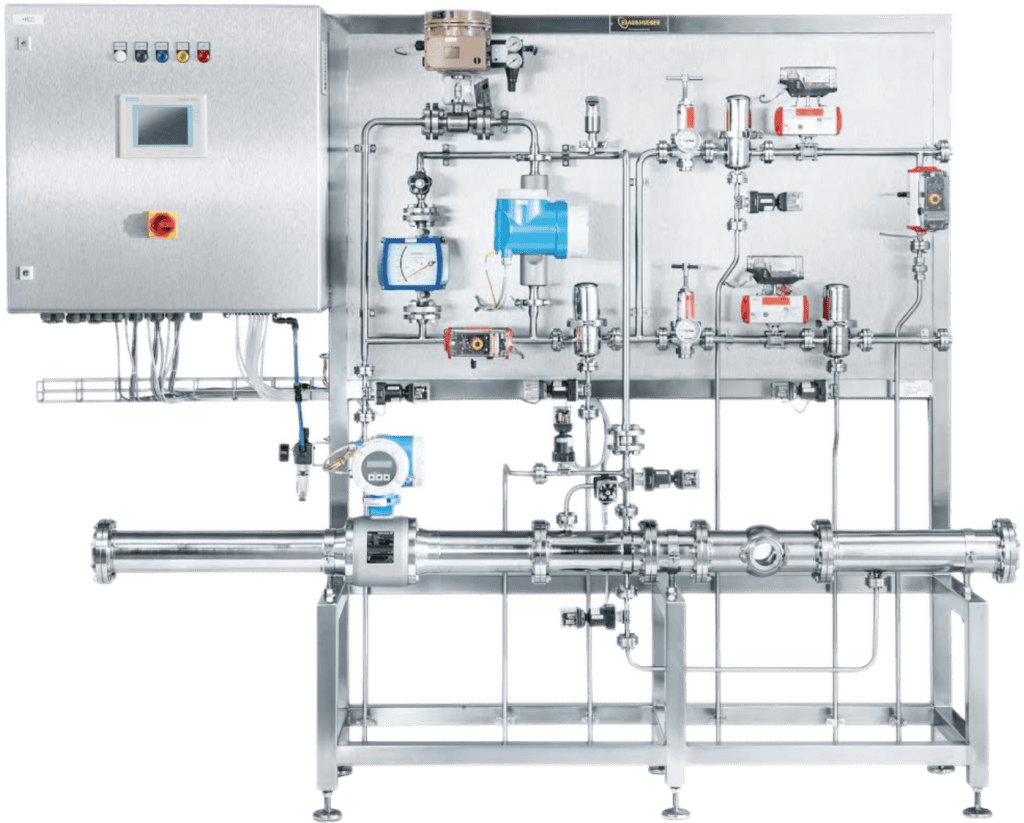

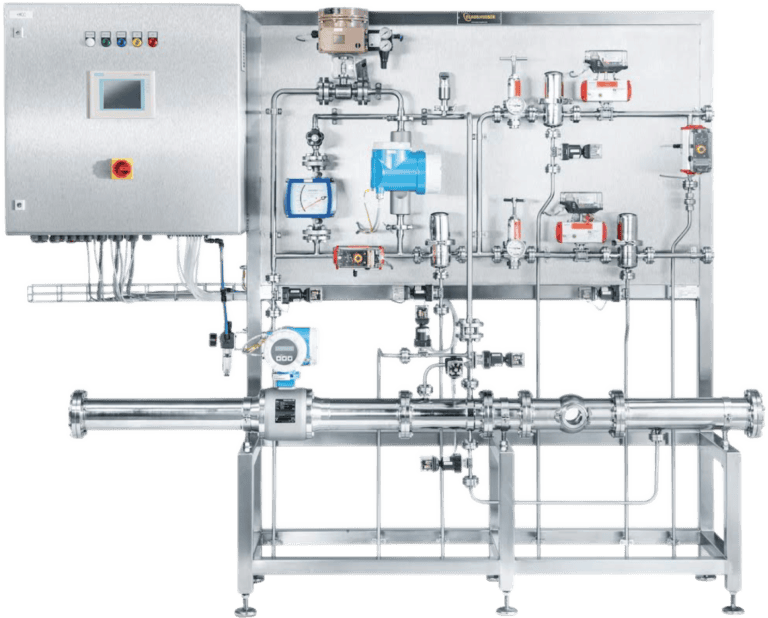

The system integrates advanced automatic control, including temperature regulation, aeration flow control, pressure management, and sterilization procedures.

A PLC-based control panel allows operators to monitor real-time parameters such as dissolved oxygen, pressure, and temperature, ensuring stable and reproducible yeast propagation. The system also includes CIP (clean-in-place) cleaning and steam sterilization functions, guaranteeing hygiene throughout the process.

The system integrates advanced automatic control, including temperature regulation, aeration flow control, pressure management, and sterilization procedures.

A PLC-based control panel allows operators to monitor real-time parameters such as dissolved oxygen, pressure, and temperature, ensuring stable and reproducible yeast propagation. The system also includes CIP (clean-in-place) cleaning and steam sterilization functions, guaranteeing hygiene throughout the process.

The yeast propagation tanks are manufactured from high-quality stainless steel with optimized structures for both direct and indirect cooling. The modular design allows flexibility in scaling capacity, typically ranging from 10L for laboratory trials to 100HL or more for industrial production.

According to customer requirements, the system can be tailored with different levels of automation, vessel configurations, and control precision, ensuring reliable yeast management for breweries of all sizes.

The yeast propagation tanks are manufactured from high-quality stainless steel with optimized structures for both direct and indirect cooling. The modular design allows flexibility in scaling capacity, typically ranging from 10L for laboratory trials to 100HL or more for industrial production.

According to customer requirements, the system can be tailored with different levels of automation, vessel configurations, and control precision, ensuring reliable yeast management for breweries of all sizes.

Copyright © 2012 – 2025 Qingdao Best Brewer Engineering Technology Co., Ltd. All Rights Reserved.