Dry milling is a conventional method for malt processing. The selected malt is conveyed to the screening machine to remove impurities, then weighed and transferred to the temporary storage bin.

Controlled by the adjustable outflow gate, the malt enters the mill for grinding. The roller spacing and gate opening can be precisely adjusted according to the required milling capacity and fineness. The finished malt powder is finally collected in the malt powder bin.

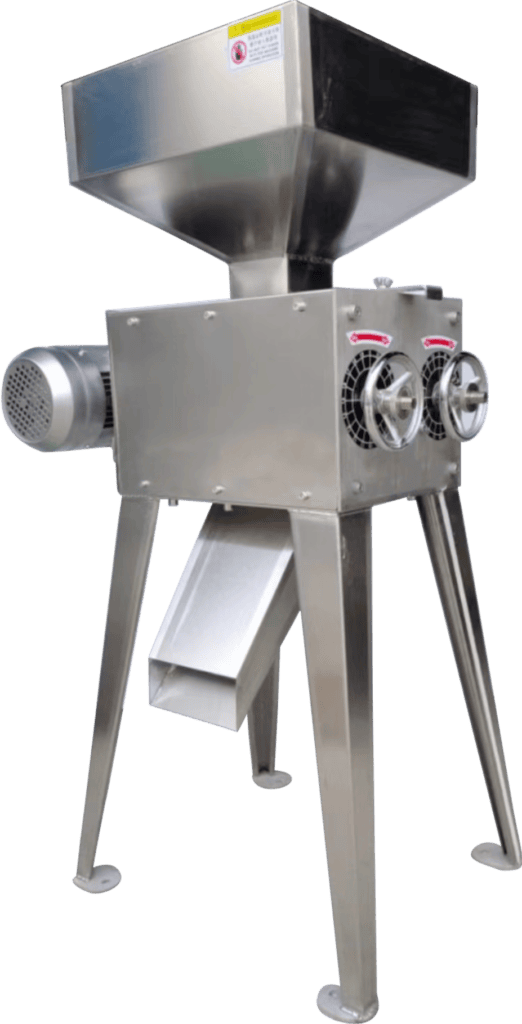

Wet milling involves soaking malt in hot water (~50 °C) for 15–20 minutes until the water content reaches about 30%. The softened malt is then fed into a double-roller mill (gap 0.35–0.45 mm) together with brewing water.

This process ensures efficient husk protection, improves wort filtration, and reduces the extraction of unwanted substances. With high milling capacity and strict hygiene requirements, wet milling is ideal for large-scale, high-quality brewing.

Wet milling involves soaking malt in hot water (~50 °C) for 15–20 minutes until the water content reaches about 30%. The softened malt is then fed into a double-roller mill (gap 0.35–0.45 mm) together with brewing water.

This process ensures efficient husk protection, improves wort filtration, and reduces the extraction of unwanted substances. With high milling capacity and strict hygiene requirements, wet milling is ideal for large-scale, high-quality brewing.

Copyright © 2012 – 2025 Qingdao Best Brewer Engineering Technology Co., Ltd. All Rights Reserved.